Stitching Change: The Power of Innovation in Fashioning a Sustainable Future

A heavy smog shrouds the community of Happyland in the Philippines, one of the poorest settlements in Manila, as piles of discarded plastic goods build up into thick layers of rubbish. Impoverished Filipinos scavenge in the rat-infested dump in search of reusable materials for resale, posing a serious threat to their health. Moreover, waste pickers burn and dismantle waste to get materials, releasing hazardous byproducts that impact human health and the environment.

Furthermore, plastics clog drains and waterways entering into estuaries and flowing out to sea, finding their way into the coral reefs affecting marine life worldwide. However, in the midst of despair two female engineers and a female scientist bring hope as they develop a revolutionary technology that can be part of the solution to the plastic pollution and waste crisis.

“Happyland,” Manila, Phillipines.

Society has undoubtedly benefited from the great engineering achievements of the 20th century, including those in the area of petroleum and petrochemical technologies, as refined forms of petroleum revolutionized almost all industries. Today, petrochemical products are everywhere, including plastics, clothing, packaging, medicine, and digital devices. However, some of these engineering achievements have adversely impacted the environment and society, particularly within marginalized groups in developing countries.

Many plastic items are useful and convenient, but they also come with a high environmental and social cost. It takes hundreds of years for plastic to degrade, so if plastic is not properly recycled, it is either littered, burned, or sent to a landfill, contaminating the environment as it breaks down into microplastics. Contrary to popular belief, plastic is not easily recycled. Only 5% to 6% of plastic waste generated in the U.S. in 2021 was recylced (World Economic Forum, 2022). The mass production of plastic in the 20th century has created a plastic pollution crisis worldwide. This issue is exacerbated in developing countries since industrialized nations ship them their plastic waste, and they lack adequate waste management systems, resulting in plastic waste piling up in massive dumps and leaking into the ocean (United Nations, 2021).

“Happyland,” Manila, Philippines.

Could 20th century engineers have anticipated that the technology they were creating could be so detrimental to the environment and society? The diversity deficit in the engineering field limits engineers from considering design constraints. In 2021, women made up only 17% of the engineering workforce in the U.S (Bosworth, 2022). Unlike other professions, such as medicine, engineers do not have a direct interface with society (Aslaksen, 2015), so there is even a greater need to work in a diverse community to gain different perspectives. Collaboration among diverse groups is essential to produce innovative technologies that can solve real-world problems. The evolution of society depends on the development of technology in which engineers play a major role. Therefore, the different viewpoints, expertise, and life experiences that come with diversity will boost engineers to address a wider range of design constraints, leading to inclusive technology.

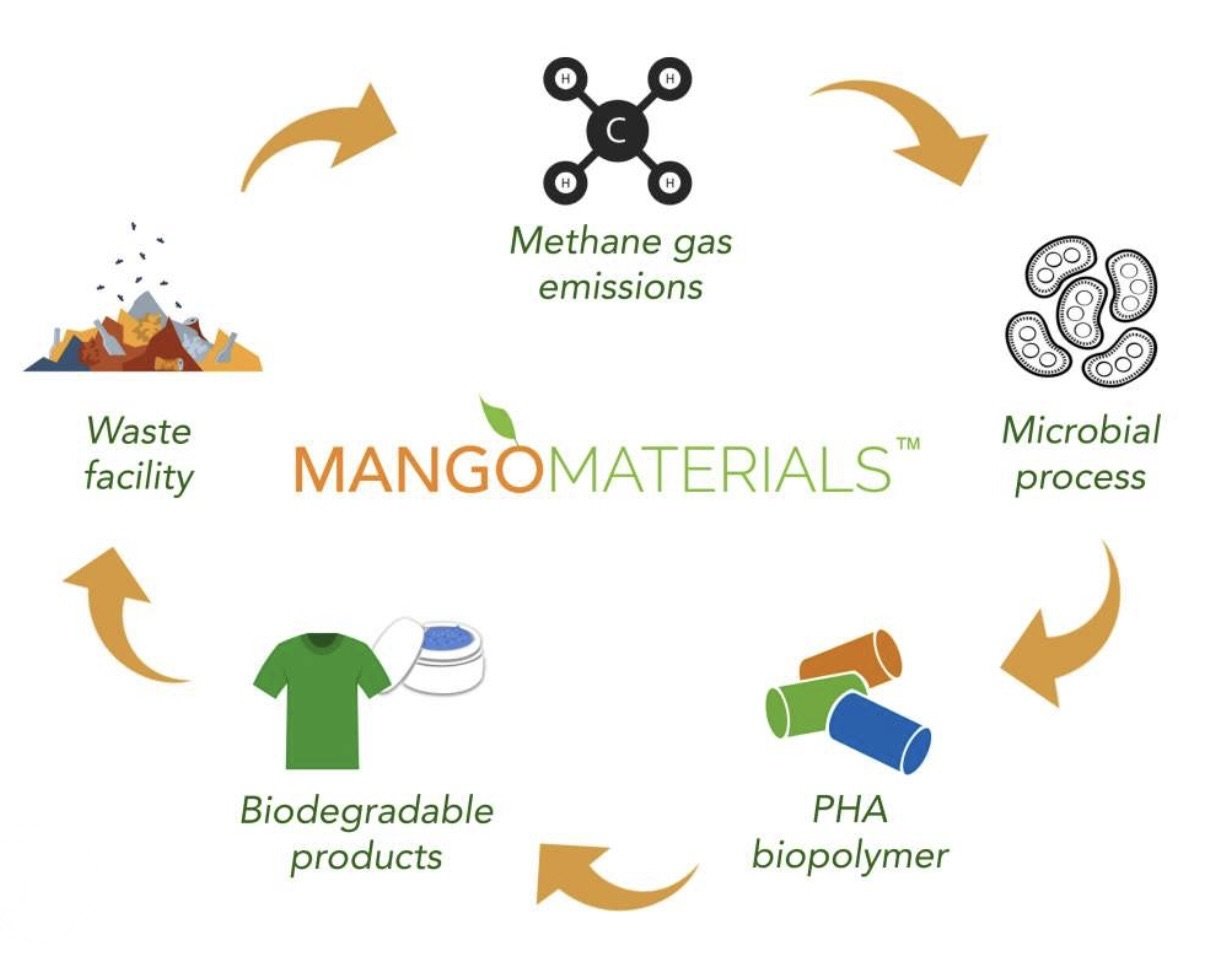

Mango Materials, a company specializing in renewable byproducts, is a testament of how diverse teams can spearhead innovative and inclusive solutions. Founded by female engineers Molly Morse and Allison Pieja and microbiologist Anne Schauer-Gimenez, Mango Materials developed an innovative technology that converts methane into a bioplastic.

While developing this technology, the all-female team considered multiple design constraints. Currently, fossil fuels serve as the primary raw materials for plastics. In contrast, Mango Materials uses methane, an abundant gas, facilitating a low-cost, highly scalable process.

The methane is used to nurture bacteria that naturally generate a biopolymer. This biopolymer is then manufactured into pellets that can be seamlessly integrated into any supply chain, ultimately being converted into biodegradable bioplastic.

When these eco-friendly plastic goods are properly discarded, they biodegrade naturally back into methane, creating a closed-loop cradle-to-cradle process. Remarkably, even if these alternative plastics find their way into the ocean, they naturally decompose in about six weeks.

While Mango Materials is still in its developmental stages, it has already received recognition from various prestigious organizations, including NASA. The company has also partnered with many industries producing commercialized products and making prototypes . Through its innovative process, Mango Materials invites us to imagine a brighter, more sustainable future.

The switch from conventional plastic goods to biodegradable alternatives addresses two critical issues: plastic pollution and waste management. Once again, greater diversity leads to more comprehensive, inclusive, and innovative solutions that provide everyone, including the people of Happyland, the quality of life that they deserve.